Strict quality control is maintained at every stage of manufacturing. Investment casting are of radiographic quality and chemical composition, physical properties and heat treatment standard laid down by the American Society of Testing Materials. Radiographic inspection is carried out as per the requirements. The system of stagewise inspection of various components for dimensions & other properties are followed strictly & records maintained.

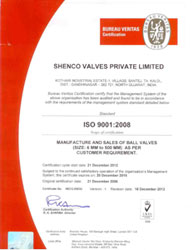

The company manufactures the valves according to ASTM, BS, STANDARDS. Management system of the SHENCO VALVES PVT LTD has been audited and found to be in accordance with the requirements of the standard as an ISO 9001:2000 BY Burear veritas Company also certified as fire proof and fire safe certification for ball valves as per API standers BY Burear veritas WE ALSO ENTERTAIN THIRD PARTY INSPECTION AS PER CLIENTS REQUIREMENTS.

- Lighter in weight reduces stress corrosion.

- Radiographic quality, dimensional tolerances upto +/- 0.003mm.can be achieved.

- Excellent, smoother, surface finish, better resistant to surface corrosion.

- Since molten metal is poured in pre-heated moulds the resultant cooling rate thus being slow, produces large grain size as well as sounder and denser casting.

- Better grain structure to ASTM number 7-9 at 100 x equivalent to forging materials as against sand casting number 5 to 7 at 100x.